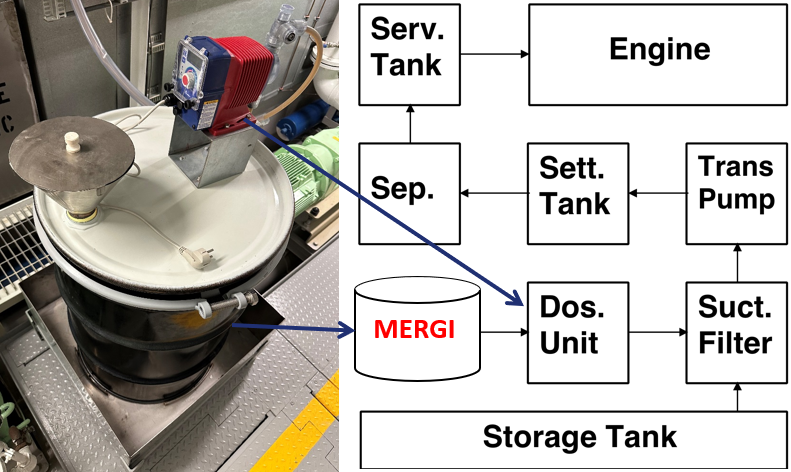

Installation of dosage pump, and injection of MERGI

MERGI is an effective liquid organic combustion catalyst, which chemically treats the fuel. When added to fuel – in the ratio of 1:4000 – it alters the structure of hydrocarbon molecules, thereby increasing oxidation during burnout. As a result, the fuel burns more completely, generating more energy from the same volume of fuel and reducing the amount of fuel wasted in exhaust emissions (soot).

The chemical treatment of fuel by MERGI takes about 10 hours. If injected into or after the service tank, MERGI will have insufficient time to treat the fuel before it is injected into the engine, resulting in little or no effect. To ensure there is enough time for the fuel treatment, MERGI should be injected with a dosage pump before the settling tank, as illustrated.

Information about the combustion process, deterioration and how MERGI works

Innovations in engine design, like turbocharging and direct injection, have been steadily improving engine efficiency. However, today’s fuels have difficulty meeting the requirements of modern engines. This is mainly due to the deterioration in fuel quality.

Deterioration of marine fuel quality

In the 1950s, refineries processed crude petroleum by atmospheric distillation, producing straight-run distillates and residual fuels. Since then, the quality of marine fuels has deteriorated as catalytic cracking has become standard and modern marine fuels, although their caloric value has remained the same, have poor combustion characteristics. The catalytic process: Petroleum-based liquid fuels contain many hydrocarbons. To convert these fuels into energy, combustion must take place. The result of complete combustion is water and carbon dioxide. Incomplete combustion produces carbon monoxide, soot, and tar. Small and light hydrocarbon molecules, like those found in gas and naphtha, burn easily. The large and heavy hydrocarbon molecules in residual fuel oil are not easily ignited, so they need a higher temperature to achieve complete combustion. In the combustion process, the creation of free radicals affects the speed of combustion. Thermal cracking occurs in molecules when a sufficient temperature is reached. The components that are created during thermal cracking are extremely reactive and immediately seek to combine with oxygen atoms. This oxidation releases heat, which leads to further thermal cracking. A chain reaction is thereby created.

How MERGI Works

The MERGI Combustion Catalyst significantly enhances the ignition quality of fuels, releasing more energy, reducing hydrocarbon residues, and leading to cleaner emissions. Specifically, the catalyst reduces ignition delay and improves combustion efficiency. Better combustion results in cleaner piston rings, ensuring a tighter fit between rings and liner. Early increase in the concentration of free radicals improves the combustion process, leading to much more intense combustion once oxidation commences. This results in a more complete combustion of the fuel, which increases the temperature that allows the oxidation of soot and tar—hydrocarbons with a low hydrogen content that might otherwise form deposits in the engine or be expelled as pollution. Complete combustion not only reduces carbon monoxide but also increases the energy released from the fuel. The resultant high temperature improves the condition of valves and piston rings by burning off soot and carbon deposits, thereby enhancing compression. This results in less cylinder leakage, thereby optimizing engine efficiency and fuel economy.

Additionally, MERGI is designed to effectively disperse asphaltenes in fuel. Asphaltenes, complex and heavy molecules found in crude oil, can lead to operational issues such as clogging filters and forming deposits in engines when they agglomerate. By incorporating MERGI into the fuel, it helps evenly distribute these asphaltenes throughout, preventing the formation of large clusters or sediments that could cause operational difficulties. This dispersion enhances the fuel’s flow and combustion properties, while also reducing the risk of blockages and deposits in the fuel system and engine. The illustration (see image) effectively demonstrates how MERGI interacts with asphaltenes to ensure smoother and more efficient engine operation.

In result, this process leads to enhanced and more complete combustion, resulting in lower fuel consumption and significantly reduced emissions of NOx, CO, and particulate matter (PM), ensuring a smoother and more efficient operation.